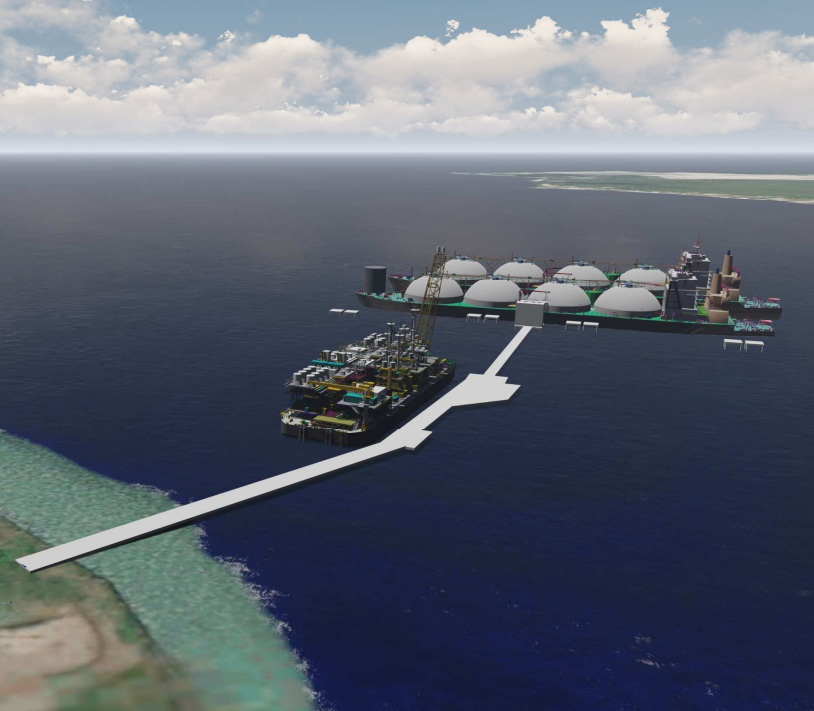

Dixstone has been awarded the Construction, Procurement and Integration of their new LNG Project in Cap Lopez, GABON

Read more: Near shore Liquefaction barge + LNG storage awarded to Dixstone!

After a long tow, starting from our yard in The Netherlands the Magisus was successfully installed in the challenging estuary of the Congo river in DRC. All those operations were made possible thanks to the know-how and assets from Dixstone.

5 years after launching Dixstone jack-ups conversion activities in the Netherlands, Dixstone is strengthening its strategic positioning in the North Sea with the purchase in December 2023 of the Yard in Vlissingen, close to the ports of Rotterdam and Antwerp.

Read more: Netherlands Yard Acquisition & Environmental Permit Granted

The 13th patented self-elevated offshore platform “Fololo” offering a 120 tone, 300sq meter deck up to 30meters water depth has been installed by Dixstone teams in Gabon.

The MSV COBEIA has recently been hired by Perenco T&t and its partners, Heritage Petroleum and the National Gas Company (NGC), as part of their $200 million three-year refurbishment program to modernize the TSP fields by electrifying the offshore platforms and replacing the existing export pipeline connecting the field to the onshore Terminal at Galeota.

Read more: The COBEIA successfully completed Pipe & cable laying campaign in T&T

©2025 Dixstone Netherlands N.V. | Design by Emogy